Features

Benefits

Applications

TV Pipe Series Valve Specifications

Temperature Range:

- -450° to 100°F (5 – 311K)

Operating Pressure:

- Bubble Tight tested to 150 psig (10.3 Bar)

Valve Class (ASME 16.34):

- Standard Class 300

- Manual Working Pressure 720 psig (49.6 Bar)

| 840 | 840FC | 1315 | 2375 | 4500 | |

|---|---|---|---|---|---|

| Inner Pipe Size | 1/2" NPS | 1/2" NPS | 1" NPS | 2" NPS | 4" NPS |

| Pipe Inner Diameter | .71" (18 mm) | .71 (.19 mm) | 1.185" (30.1 mm) | 2.209" (57 mm) | 4.125" (104.8 mm) |

| Cv (Kv) - Globe | 2.4 (4.02) | 1.07 (.86) | 14 (14.8) | 20 (17.2) | 191 (165.2) |

| Cv (Kv) - "Y" Pattern | 3.0 (4.28) | N/A | 15.6 (5.17) | N/A | N/A |

| Heat Leak in BTU/HR (watts) | 4.8 (1.0)* | 4.8 (1.0)* | 7 (1.86)* | 7.9 (1.89)* | 21 (4.5)* |

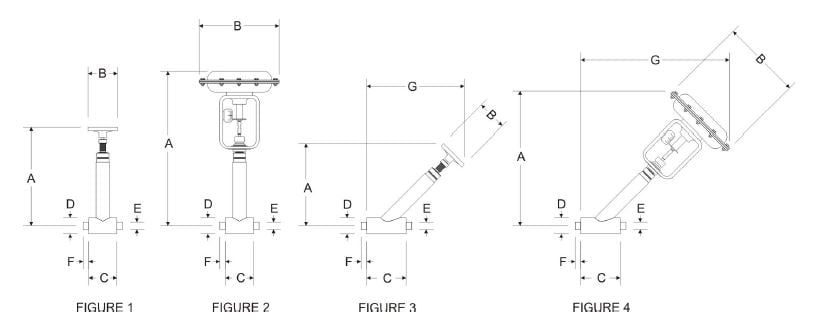

Valve Installation Dimensions

All Dimensions in Inches (mm). *Fully Open

| TV-GM-0840 | Figure 1 | 14.1 (358)* | 2.6 (66) | 3 (76) | 2.375 (60.3) | .840 (21.3) | .5 (13) | N/A |

| TV-GP-0840 | Figure 2 | 19.6 (498) | 9 (229) | 3 (76) | 2.375 (60.3) | .840 (21.3) | .5 (13) | N/A |

| TV-YM-0840 | Figure 3 | 11.2 (284)* | 2.6 (66) | 4 (102) | 2.375 (60.3) | .840 (21.3) | .5 (13) | 12.4 (315)* |

| TV-YP-0840 | Figure 4 | 16.6 (422) | 9 (230) | 4 (102) | 2.375 (60.3) | .840 (21.3) | .5 (13) | 17.8 (452) |

| TV-GM-0840-FC | Figure 1 | 14.4 (366) | 2.6 (66) | 3 (76) | 2.375 (60.3) | .840 (21.3) | .5 (13) | N/A |

| TV-0840-FC | Figure 2 | 21.4 (545) | 8.5 (22) | 3 (76) | 2.375 (60.3) | .840(21.3) | .5 (13) | N/A |

| TV-GM-1315 | Figure 1 | 18.7 (476)* | 6 (150) | 5 (127) | 2.875 (73) | 1.315 (33.4) | 1.0 (25) | N/A |

| TV-GP-1315 | Figure 2 | 24.6 (625) | 11 (279) | 5 (127) | 2.875 (73) | 1.315 (33.4) | 1.0 (25) | N/A |

| TV-YM-1315 | Figure 3 | 15.8 (402)* | 6 (152) | 7 (178) | 2.875 (73) | 1.315 (33.4) | 1.0 (25) | 19.6 (498)* |

| TV-YP-1315 | Figure 4 | 20.2 (513) | 11 (279) | 7 (178) | 2.875 (73) | 1.315 (33.4) | 1.0 (25) | 24 (610) |

| TV-GM-2375 | Figure 1 | 23.8 (605)* | 6 (152) | 7 (178) | 4.50 (115) | 2.375 (60.3) | 1.5 (38) | N/A |

| TV-GP-2375 | Figure 2 | 31.3 (795) | 13.1 (333) | 7 (178) | 4.50 (115) | 2.375 (60.3) | 1.5 (38) | N/A |

| TV-GM-4500 | Figure 1 | 36.2 (920) | 10 (254) | 14 (356) | 6.625 (169) | 4.5 (115) | 1.5 (38) | N/A |

| TV-GP-4500 | Figure 2 | 59.3 (1506) | 16 (406) | 14 (356) | 6.625 (169) | 4.5 (115) | 1.5 (38) | N/A |

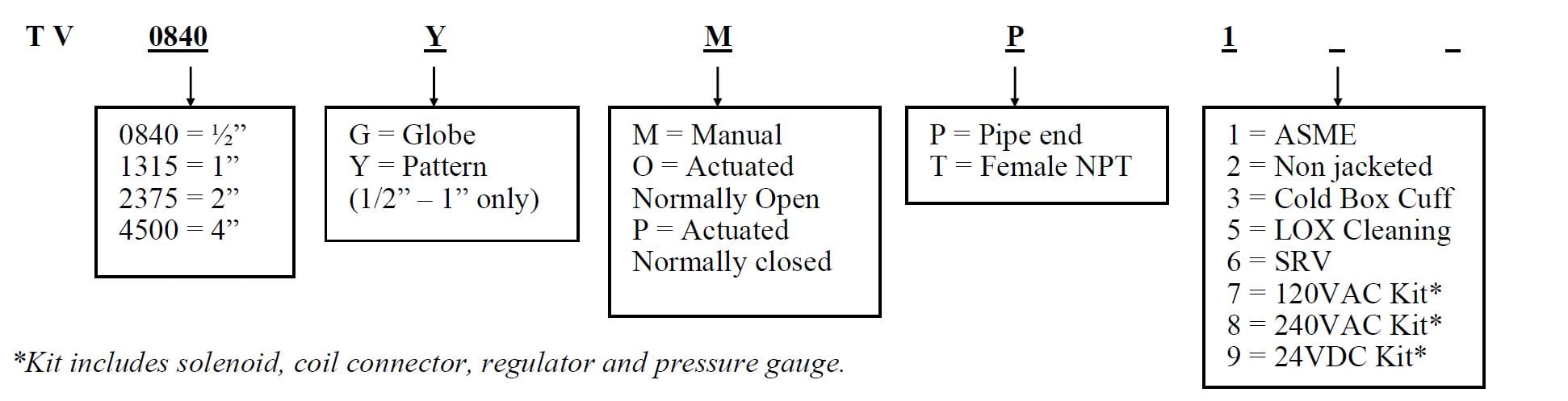

Valve Nomenclature