CRYOWorks and Technifab proudly partner with architects and contractors to create state-of-the-art biological laboratories and research facilities. These facilities drive various breakthroughs in the fields of cell culture, biobanking, microscopy, and cryosurgery, while also storing biologic samples, vaccines, and medicines. Liquid nitrogen is the common medium used in each application and is provided from bulk tanks as portable dewars.

With over 325 years of combined experience in cryogenics, we’ve guided numerous biological lab and cryogenic storage facilities to optimize their liquid nitrogen use, reduce construction costs, and ensure the longevity of the system. Not only do we provide the products and equipment that deliver the cryogenic fluids to their end points, but we also offer our extensive engineering and project management services.

Through our experience, here are two common scenarios we come across:

1. Is there a right way to connect a dewar to a manifold?

Like anything else, there’s the wrong way, a good way, and a better way to connect to a dewar.

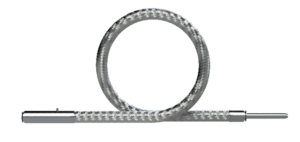

WRONG WAY

The wrong way has the hose coiled up such that a high point exists. This might be done to “tidy the workspace”, reduce stress on the hose ends, or for some other means. This creates an artificial high point in the hose which will act as a gas trap, slowing or preventing liquid from flowing.

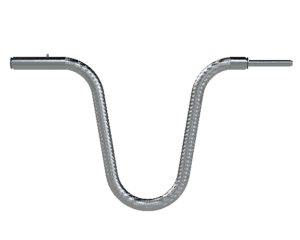

GOOD WAY

Then, there’s an efficient installation. In this example, there are no artificial high points and gas traps. We allow the hose to droop in the natural U-shaped bend that the hose wants to hang. Liquid is allowed to flow freely to the use point. There is a potential drawback to this configuration. If the hose is allowed to hang as shown, there is a risk that over time it can weaken and need replacement or repair. This is compounded with dewars that are frequently disconnected and replaced.

IDEAL WAY

Finally, there is a better way to install. In this case, the hose is allowed to hang like in the previous example, but by using an attachment off the dewar and manifold, it will enable the hose to hang straight down. Doing so eliminates the stress on the hose from turning down at the ends, and dramatically improves longevity while still allowing good flow of liquid to the use point .

2. What is something to consider in designing new labs/research facilities?

For architects, the layout of a new floor plan is crucial for maintaining project budgets and ensuring efficient, functional facilities. Considerations include workflow, access, security, and balancing engineering and construction costs. For cryogenic storage vaults and labs, layout significantly impacts the cost of installing Vacuum Insulated Pipe, especially in multi-level facilities. Stacking cryogenic storage rooms, labs, and use points vertically is generally recommended.

As seen with this first example, the storage vaults and labs in this multi-story facility were designed without consulting cryogenic experts like CryoWorks and Technifab. Although the building’s flow was well-planned, the piping was overlooked. This resulted in a functional system but with added costs around additional liquid nitrogen supply piping, gaseous nitrogen vents, liquid conditioning accessories like Keepfull Devices, and other expenses

In this example, the same building is shown, and with our cryogenic expertise, it’s been designed with cryogenic use points stacked vertically. This design reduces the number of liquid nitrogen supply pipelines that drop from the roof, the number of gaseous nitrogen vent lines, and the equipment needed to condition the liquid before use. The result is a simplified system and lower total project costs.

For any critical application, it’s important to consider the multitude of factors, especially in its’ design. Partner with us early to avoid nuances and break ground sooner!